Sustainability in Automobile Industry - A TATA Case Study

In the rapidly evolving landscape of the 21st century, designing and manufacturing sustainably is the need of the hour. This transformative change is particularly important in the automotive industry. “Historically, the automotive industry has not focused on sustainable practices” (SAP BRANDVOICE, 2021). Traditionally, the manufacturing processes in the automotive industry are not quite environment-friendly with large amounts of consumption of energy, metals, plastics toxins etc. which eventually leave behind a hefty carbon footprint (SAP BRANDVOICE, 2021). Following that, post manufacturing, the automobile operates on fossil fuels which further releases harmful emissions which has drastically affected the environment for the worse (SAP BRANDVOICE, 2021).

The automotive industry’s plan towards achieving sustainability is a response to address the climate change crisis and The Paris Agreement which is a “legally binding international treaty on climate change” (United Nations Climate Change, n.d.) that talks about limiting the global temperature to 1.5˚C up till the end of this century (United Nations Climate Change, n.d.). This reflection and reaction towards sustainability is not just compliance, but also, a fundamental reevaluation of the industry’s contribution in global well-being. This paper aims to undertake a comprehensive examination of sustainable strategies adopted by the global automotive industry with a specific focus on the Indian automotive manufacturing giant, Tata Motors Ltd.

Indian Automotive industry is a pivotal contributor to the global market with its rapid growth and evolution into the sustainable solutions. Like many manufacturers focusing their vision to advanced technological solutions and sustainable practices, Tata Motors is obliged to integrate sustainable practices in its core value and operations followed by unique challenges and opportunities innate to the Indian subcontinent.

In this research, our methodology involves a focused analysis of Tata Motors sustainability initiatives like Green House Emissions, Waste and Water Management and especially on the company’s plans towards achieving Net-zero emissions (TATA Motors, 2022). This approach would be executed using a comprehensive analysis of the sustainable practices undertaken by Tata motors and then discuss their success and future scopes.

Figure 2 Electric Charger being plugged into an Electric Vehicle. Available at: Tatamotors.com (13 December,2023)

The automotive industry is one of the foundational contributors of the modern society and as long faced criticism for its significant contribution to climate change. As the concerns about global warming and air pollution are increasing, the automotive industry is also undergoing a transformative change towards sustainability. This literature review aims to provide a comprehensive examination of the current sustainable practices in the automotive industry like sustainable vehicle technologies, sustainable manufacturing processes, and supply chain. Through the comprehensive examination, this review aims to highlight challenges and opportunities in sustainability in the automotive sector.

SUSTAINABLE VEHICLE TECHNOLOGIES

Global automotive industry holds a crucial role in global economy but is also advancing in research and development. Advanced technologies are being designed and introduced to maximize passenger safety (Sanguesa, et al., 2021). However, due to an unprecedented rise in the vehicle population on roads has drastically affected the air pollution in urban areas with particulate matter like particulate matter (PM), nitrogen oxides (NOX), carbon monoxide (CO), sulfur dioxide (SO2) (Sanguesa, et al., 2021). To minimize this, sustainable vehicle technologies are playing a pivotal role in this transformation, by offering innovative technologies to enhance fuel efficiency and promote renewable energy consumption. Following are a few examples:

Figure 3 Man charging his car from a public charger. Available at – freepik.com (Accessed 13 December 2023)

ELECTRIC VEHICLES (EV)

This is global climate crisis, Electric Vehicles (EV) have emerged as a beacon of hope for a cleaner and sustainable future. These automobiles operate on electricity and rechargeable lithium-ion battery eliminating tailpipe emissions and significantly reducing the carbon footprint.

PLUG-IN HYBRID ELECTRIC VEHICLES (PHEV)

“PHEV’s transition between conventional and electric vehicles and possess great potential in real-life crisis” (Liu & Liu, 2022). PHEV’s are usually comprised of an internal combustible engine and an electric motor with external power supply (Liu & Liu, 2022). And significant electricity is being stored off the grid using PHEV’s to efficiently reduce fuel consumption in regular driving conditions (Sanguesa, et al., 2021).

HYDROGEN FUEL CELL ELECTRIC VEHICLES (FCEV)

Figure 5 Functioning of a FCEV Vehicle. Available at: bmw.com (14 December 2023)

Although, in its initial stages hydrogen infrastructure and fuel cell technology has made strides in the automotive industry. Fuel cell is an electricity producer which consists of an anode and a cathode where hydrogen and oxygen are used as basic fuels to conduct a chemical reaction that produces electricity with very less amount of pollution (Muthukumar, et al., 2021). Unlike EV’s, FCEV’s do not rely on lithium-ion batteries, thereby eliminating range anxiety and allowing quicker refueling, however, this technology still requires further development to make FCEV a viable option.

BIOFUELS AND RENEWABLE ENERGY SOURCES

Figure 6 Infographic Explaining the concept of Bio-Fuels. Available at: renovare-fuels.co.uk (14 December 2023)

“Hydrocarbon fuels have ruled the transportation and the automotive industry due to their high energy density, ease of handling, storage and transportation” (Yu, et al., 2020). However, batteries and fuel cells and other alternatives are getting popular due to their lower carbon footprint and potential to reduce reliance on fossil fuels (Yu, et al., 2020).

To match with the competitive market, alternative energy resources are being researched for various reasons like sustainable energy, energy security and environmental protection, a few examples of hydrocarbon alternatives are – Natural Gas (NS), Liquified Petroleum Gas (LPG) and other biofuels like ethanol, biodiesel etc. (Yu, et al., 2020).

Furthermore, renewable energy sources like wind, tidal and solar have been around and growing for a while, but, Tesla became a pioneer of integrating renewable energy technologies in the automotive sector by collaborating with SolarCity, and allowing its batteries to be powered by the sun by converting solar energy into electricity without releasing harmful pollutants (Maradin, et al., 2022).

LIGHTWEIGHT MATERIALS IN AUTOMOBILES

With growing challenges in climate change, global warming and specially in fuel efficiency in the automotive industry, has compelled manufacturers to produce lightweight automobiles which in turn might contribute in “superior recyclability and vehicle performance (e.g. driving economy, braking behaviour etc.) (Zhang & Xu, 2022).

Figure 7 . Representative lightweight materials applicable for different components of automobiles, including light alloys (e.g., aluminium, magnesium, and titanium alloys), HSSs, composites (e.g. CFRP), and advanced materials (e.g., metamaterials).Available at: (Zhang & Xu, 2022)

SUSTAINABLE MANUFACTURING PRACTICES

Adhering to the impositions by various governments who participated in The Paris Agreement, the automotive industry is undergoing a transformative change towards sustainable manufacturing practices. Automakers are following and adopting various strategies and technologies throughout their manufacturing process. Following are a few examples:

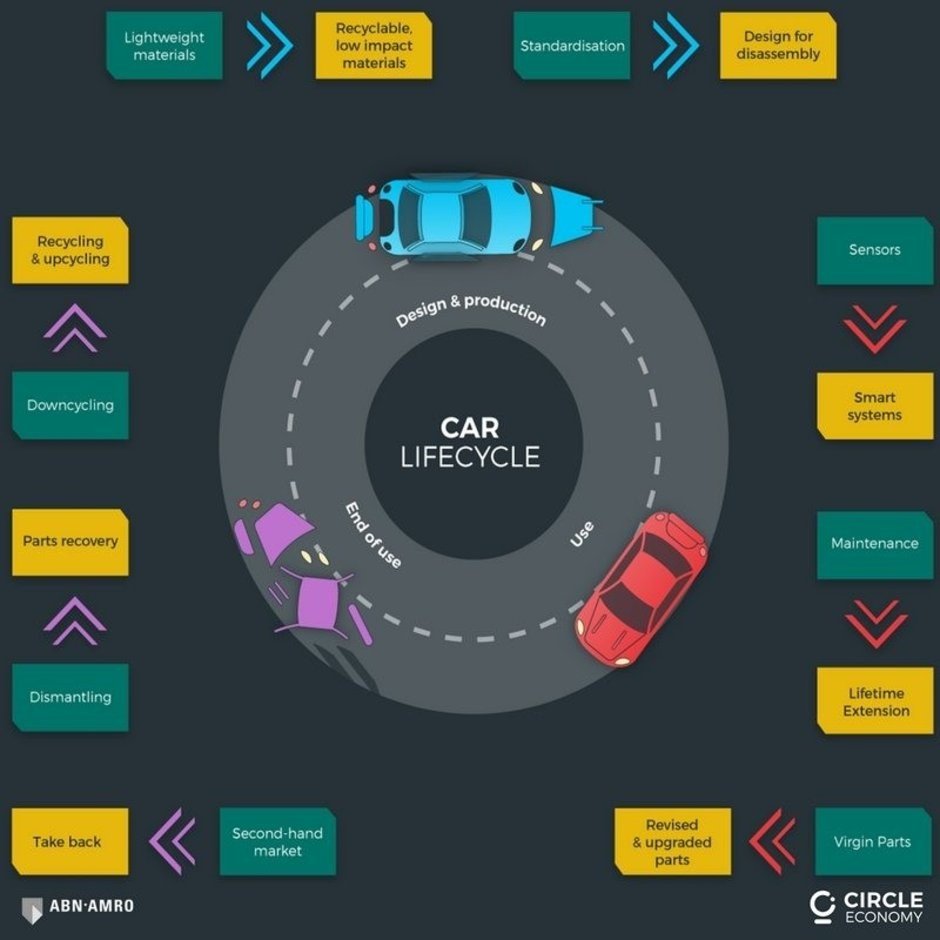

CIRCULAR ECONOMY

Figure 8 Infographic Explaining circular economy in Automotive Industry. Also Available at: foundary-planet.com (13 December 2023)

Conceptualized in the 1960’s, the concept of circular economy is being adapted across many industries (Maldonado-Guzman, et al., 2021). The concept speaks about products and processes and the minimization of negative impacts on the environment and nonrenewable resources along with the exclusion of toxic materials with potential reuse of materials and products (Maldonado-Guzman, et al., 2021). The term ‘circular’ is inspired from natural ecosystems and aims to replicate and create a regenerative economy (Maldonado-Guzman, et al., 2021). Automotive industry is also incorporating this concept by focusing on extending lifespan of vehicles, their components and materials.

WASTE MANAGEMENT

The automotive industry is rapidly shifting from using conventional petroleum-based plastics to renewable sources like bioplastics, natural-fiber composites and reinforces polymer composites (Vieyra, et al., 2022). Although, they too have their limitations such as low mechanical properties and thermal degradation, despite which, automakers like Toyota and Ford are actively incorporating it in their vehicles as a step forward to a sustainable future (Vieyra, et al., 2022).

SUSTAINABLE SUPPLY CHAIN MANAGEMENT (SSCM)

Transformation towards sustainability in the industrial sector started with, “the report by the World Commission on Environment and Development (WCED) in 1987” (Masoumi, et al., 2019), which emphasized on the inclusion of sustainable initiatives in business practices. The automotive industry is highly pressurized to adhere to sustainable practices due to its large carbon footprint (Masoumi, et al., 2019). And it is doing so by introducing various stages of Automotive Supply Chain Management, designing – by keeping in mind the use of sustainable design strategies, purchasing – by investing in renewable supplies as raw materials, supplier collaboration – collaborating with renewable raw material suppliers, logistics – by mitigating and streamlining automated and human-powered processes etc. (Masoumi, et al., 2019).

CASE STUDY: TATA MOTORS LIMITED

Figure 9 1945 - Manufacturing of locomotives and other engineering products. Also available at Tatamotors.com (13 December 2023)

Tata Motors Ltd. with a turnover of $42 billion, is India’s largest automobile company and a global leader in the design, manufacturing and sales of a diverse portfolio of automobiles such as – passenger cars, public buses, commercial vehicles like trucks and even defense vehicles. Founded in 1945, Tata Motors Group, formerly TELCO is a part of $100 billion Tata Group which was established by Mr. Jamsetji Nusserwanji Tata (TATA Motors Limited, n.d.). The company is well-known for its world-class quality, innovation, engineering and design excellence (TATA Motors Limited, n.d.). Guided by the principles of sustainability and giving back to the community, Tata Motors is committed to a strong corporate citizenship and is at the forefront of shaping the future of India’s automotive industry (TATA Motors Limited, n.d.).

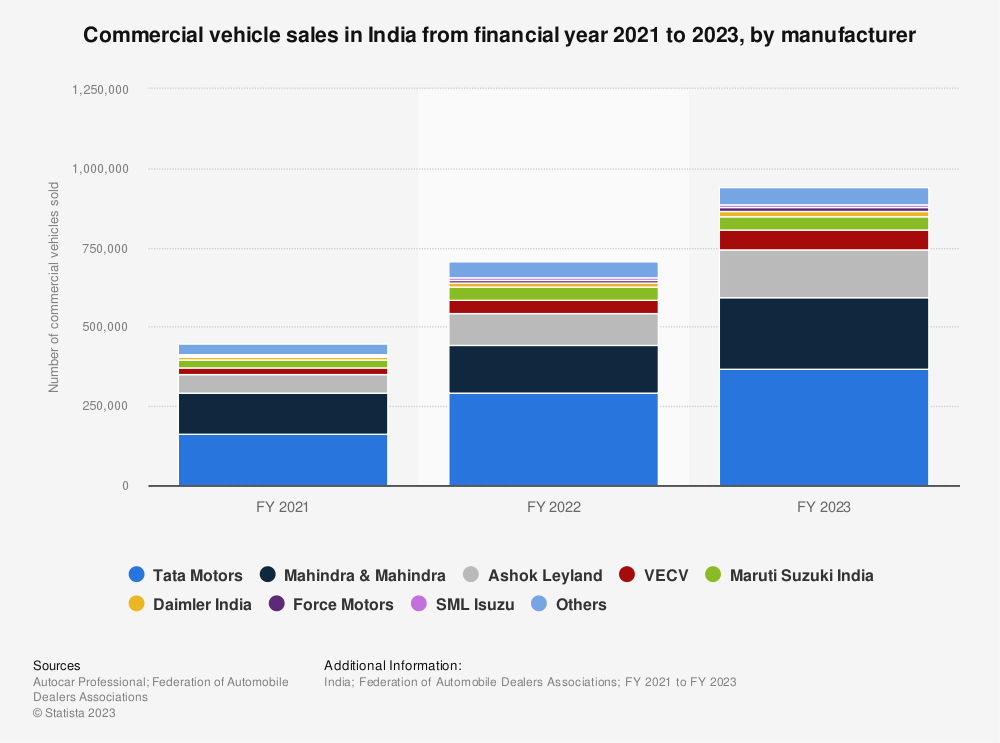

Tata Motors has positioned itself as the leader in India’s commercial vehicle market segment with a 45.1% market share in FY 2018-19, Tata motors has powerful presence, serving over 175 countries (Jebakumar S. & Devi, 2023).

Table 1 Statistical Data of Commercial Sales of TML in india from FY 2021-23, Available at: Statista (13 December 2023)

TML boasts a network of 134 subsidiaries in India and internationally offering a variety of engineering and automotive solutions. Amongst those, are Jaguar Land Rover in the United Kingdom and Tata Daewoo in South Korea, contributing to the organization’s global automotive operations.

Tata motors has adopted a comprehensive strategy for achieving Net Zero including its business and operational impact and strategy (TATA Motors, 2022). The company aims to integrate sustainability in its business model by emphasizing on three factors: reducing the carbon footprint of its business and value chain, using a circular economy approach to minimize resources and corresponding waste, and taking further steps to protect and restore the environment (Tata Motors Limited, 2022).

Figure 10 Tata Motors Sustainability Pillars. Available at: 78th Integrated Annual Report FY2022-23. (14 December 2023)

Renewable Energy Action Plan and Net Zero - Tata Motors aims to achieve Net Zero by a product driven and operations driven approach. The company aims to convert all of its Private Vehicles and Commercial Vehicles into Net-Zero generating products by 2040 and 2045 respectively. Furthermore, the company targets to source 100% of its electricity through renewable sources by 2030 (TATA Motors, 2022). Adhering to Sustainable Manufacturing Practices, Tata motors continued to install Solar photovoltaic cells at all of its assembly lines which can be seen from the data Below.

Table 2 Table Explains Renewable Energy (Solar) Generation Capacity in FY 2022-23 (in MWp). Created through data from: 78th Integrated Annual Report FY2022-23. (14 December 2023)

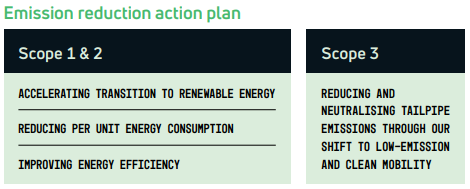

Greenhouse Gas and Action Plan - Tata Motors Limited (TML) aims to reduce Greenhouse Gas (GHG) emissions through a three scope action plan as shown below:

Table 3 Emission Reduction Action Plan. Available at: 78th Integrated Annual Report FY2022-23. (14 December 2023)

As per Figure 11, TML aims to transition into renewable energy while also reducing per unit energy consumption and improving energy efficiency in its two out of three scope action plan. While the third scope aims on reducing and neutralizing tailpipe emissions through their product plans which involve a whole portfolio of clean alternatives like Battery Electric Vehicles (BEV), Hydrogen Fuel Cell Vehicles (FCEV) and Hydrogen ICE vehicles.

Water Management - TML acknowledges the significance of water as a shared and limited source. The company aims to recycle and re-use water efficiently at all of its manufacturing plants and has done so by creating water bodies and introducing ground water recharging strategies wherever possible (Tata Motors Limited, 2022). Despite none of its manufacturing plants are at water-stressed regions, TML is cautious about water source management (Tata Motors Limited, 2022). Recently, the Lucknow facility and the Pantnagar facility received ‘Water Positive” and ‘Water Neutral’ certification by CII-GBC for FY 2022-23 (TATA Motors, 2022).

Waste Management - Following the strict protocol and legalities associated with permits, consents and authorizations, Tata Motors Ltd consciously segregates its waste in an orderly fashion based on material type and shape, and then subsequently sell it to authorized recyclers for conversion and utilization (TATA Motors, 2022). Old plastic and flexible packaging items are collected and sold to authorized plastic waste processors for recycling, which is then re-used to make fresh packaging material. Various e-waste is also consciously segregated and disposed to recyclers upon reaching the end of their useful life (TATA Motors, 2022).

Figure 11 Figure Depicting Waste generated by Tata Motors in FY 2022-23. Available at: 78th Integrated Annual Report FY2022-23. (14 December 2023)

Circular Economy - While working towards long-term manufacturing and business growth, Tata Motors recognized the finite nature of natural resources and is working towards strategic approaches to resolve it (TATA Motors, 2022). TML consistently works towards improving the use of virgin materials and aligning itself with a circular economy approach (Tata Motors Limited, 2022).

Figure 12 TML Circular Economy Action Plan. Available at: 78th Integrated Annual Report FY2022-23. (14 December 2023)

ELECTRIC VEHICLES - India aims to transform into a fully electric vehicles market by 2040, in order to do so, the Govt. of India initiated the Faster Adoption and Manufacturing of Electric Vehicles (FAME) Scheme in 2015 which incentivized environmentally friendly vehicles (Kumar & Hallur, 2020). Although, India is still in its initial stages with electric vehicle development with a couple of electric car manufacturers, three to four OEMs in electric buses and approximately ten manufacturers in the two-wheeler segment (Kumar & Hallur, 2020). TML is one of the first manufacturers to introduce private electric vehicles in the India Market. The company’s electric motor line sold 15,518 electric vehicles in the first half of FY2022-23 and thereby achieving an 85.53% market share followed by a total of 50,000 electric vehicles sold in the total FY2022-23 (Jebakumar S. & Devi, 2023).

Table 4 Electric Passenger Vehicle Sales in India from 2020 – 2022. Available at: Statista (13 December 2023)

RECCOMENDATIONS

Tata Motors Limited is known for its high quality and trust that has been developed over the years along with the parent company, Tata Group. TML although diversifying its portfolio still heavily relies on the commercial vehicle segment, I recommend to diversify your private vehicle portfolio (Kumar & Hallur, 2020). Furthermore, the Indian market has potential of electric vehicles considering the enormous population, launching the Tata Nexon EV was a smart move on the company’s end. Despite that, consumers suffer from range anxiety where “range” means how far can the car travel once it’s fully charged as Nexon does not match its claimed travel range of 300kms, I recommend on working on maximising the driving range. Since TML boasts of developing its entire private vehicle segment as net-zero, the company still needs to develop its innovation sector in the electric vehicle segment (Kumar & Hallur, 2020). “Major competitors such as General Motor, Mitsubishi Motor, Ford, Fiat, and so on have been quite innovative as of late, and hence Tata must try to be more innovative in the approach” (Kumar & Hallur, 2020). Being part of a parent company like Tata Group, TML spends a lot of money on research and development (R&D), I suggest on focusing and introducing more Hybrid Electric Vehicles (HEV), Battery Electric Vehicles (BEV) and Hydrogen Fuel Cell Electric Vehicle (FCEV). After the global pandemic of COVID-19, the automotive industry came to a standstill and upon resuming function, there was a high demand for vehicles, especially electric vehicles which led to a global shortage of semiconductors and lithium-ion batteries as suppliers started to ration it for future use (Kumar & Hallur, 2020). So, as a part of make-in-India initiative, I recommend Tata Motors to produce components locally in order to minimize dependence on other countries (Kumar & Hallur, 2020).

CONCLUSION

In conclusion, sustainability is not an ethical consideration but a necessity for a better future. With global crisis, climate change and environmental degradation, there is a need for automotive industry to change its operations. Tata Motors Limited is a noteworthy case example portraying commendable commitment to sustainable practices and innovation.

Being a part of a prominent parent company like Tata Group, Tata Motors have established themselves as a prominent player in the Indian and global automotive sector. TML investment on compliance with the BS6 emission standard along with investment in Electric Vehicles (EV) contributes to the global agenda of minimizing carbon footprint and reducing air pollution. Furthermore, TML has contributed significant funds in the R&D sector which aims to develop diverse range of electric and hybrid vehicles.

Tata Motors emphasis on circular economy is admirable. The integration of recyclable materials in vehicle design and a commitment to reduce e-waste and plastic waste throughout the manufacturing and product life cycle depicts a comprehensive approach towards sustainability. TML aims of achieving net-zero in private vehicles by 2040 and commercial vehicles by 2045 (TATA Motors, 2022). The company aims to be a responsible corporate citizen by adopting renewable energy sources, water conservation and regeneration measures, waste management practices etc. The journey towards sustainability is long, but Tata Motors stands as an example to the possibilities and benefits that come with environmental consciousness in the automotive industry.

References

· BStrategyhub, 2023. Bstrategyhub. [Online]

Available at: https://bstrategyhub.com/tata-motors-swot-analysis/#Tata_Motors_Strengths

[Accessed 14 December 2023].

· Jebakumar S., A. & Devi, A. J., 2023. TATA Motors Limited: A Revolution in Electric Cars - A Case Study. International Journal of Case Studies in Business, IT, and Education (IJSCSBE), April.7(2).

· Kumar, A. & Hallur, G. G., 2020. Driving the Electric Vehicle Revolution in India: A case Study of Tata Nexon. PalArch's Journal of Archaeology of Egypt/ Egyptology (PJAEE), Volume 6.

· Liu, C. & Liu, Y., 2022. Energy Management Strategy for Plug-In Hybrid Electric Vehicles Based on Driving Condition Recognition: A Review. Electronics 2022, 23 January, Volume 11, p. 342.

· Maldonado-Guzman, G., Garza-Reyes, J. A. & Pinzon-Castro, Y., 2021. Eco-Innovation and the circular economy in the automotive industry. Benchmarking : An International Journal, 28(2).

· Maradin, D., Malnar, A. & Kastelan, A., 2022. Sustainable and Clean Energy : The Case Study of Tesla Company. Journal of Economics, Finance and Management Studies, 12 December, 5(12), pp. 3531-3542.

· Masoumi, S. M., Kazemi, N. & Abdul-Rashid, S. H., 2019. Sustainable Supply Chain Management in the Automotive Industry: A Process-Oritented Review. Sustainability, 19 July.

· Muthukumar, M. et al., 2021. The development of fuel cell electric vehicles – A review. Materials Today: Proceedings, Volume 45, pp. 1181-1187.

· Pereira, D., 2023. The Business Model Analyst. [Online]

Available at: https://businessmodelanalyst.com/tata-motors-swot-analysis/#Tata_Motors_Strengths

[Accessed 14 December 2023].

· Sanguesa, J. A. et al., 2021. A Review on Electric Vehicles: Technologies and Challenges. Smart Cities 2021, 15 March, Volume 4, pp. 372-404.

· SAP BRANDVOICE, 2021. How The Automotive Industry Is Driving Toward A Sustainable Future. [Online]

Available at: https://www.forbes.com/sites/sap/2021/12/01/how-the-automotive-industry-is-driving-toward-a-sustainable-future/?sh=69de83098f1b

[Accessed 13 December 2023].

· Tata Motors Limited, 2022. 78th Integrated Annual Report 2022-23, Mumbai: s.n.

· TATA Motors Limited, n.d. TATA Motors - Our History. [Online]

Available at: https://bard.google.com/chat/ce70e384fde4222c

[Accessed 14 December 2023].

· TATA Motors, 2022. 78th Integrated Annual Report 2022-23, Mumbai: Tata Motors.

· United Nations Climate Change, n.d. The Paris Agreement. [Online]

Available at: https://unfccc.int/process-and-meetings/the-paris-agreement

[Accessed 13 December 2023].

· Vieyra, H., Molina-Romero, J. M., Calderon-Najera, J. d. D. & Santana-Diaz, A., 2022. Engineering, Recyclable, and Biodegradable Plastics in the Automotive Industry: A Review. Polymers, 21 August.Volume 14.

· Yu, X., Sandhu, N. S., Yang, Z. & Zheng, M., 2020. Suitability of energy sources for automotive application – A review. Applied Energy , Issue 271.

· Zhang, W. & Xu, J., 2022. Advanced lightweight materials for Automobiles: A review. Materials and Design, Issue 221.

Table References

Figure References

· Figure 4 Function of a PHEV Vehicle. Available at: kia.com(14 December 2023). 5

· Figure 5 Functioning of a FCEV Vehicle. Available at: bmw.com (14 December 2023). 6